The Autonomous Discrete Manufacturing Loop

- David Rogers

- 2026-01-23

The rise of vibe coding, where natural language prompts and AI-driven logic replace traditional software development, has democratized software development, resulting in an explosion of niche, highly personalized iOS and mobile applications. A similar shift could emerge in hardware through vibe CADing where generative design tools allow creators to manifest complex physical geometries through intent rather than technical drafting expertise. This evolution is poised to transform the industrial sector, enabling a new wave of agile industrial companies to rapidly prototype and bring specialized industrial goods to market with unprecedented speed.

In a bizarre way, it has been an ACCELERANT for OUR SALES to help our customers see that we’re leveraging … this AI … and here’s how it’s ultimately going to get you better end products, for cheaper.

From the Anduril COO on how partnering with Dirac surprisingly helps accelerates sales /X/

1. Intent-Based Design Synthesis (Vibe CADing)

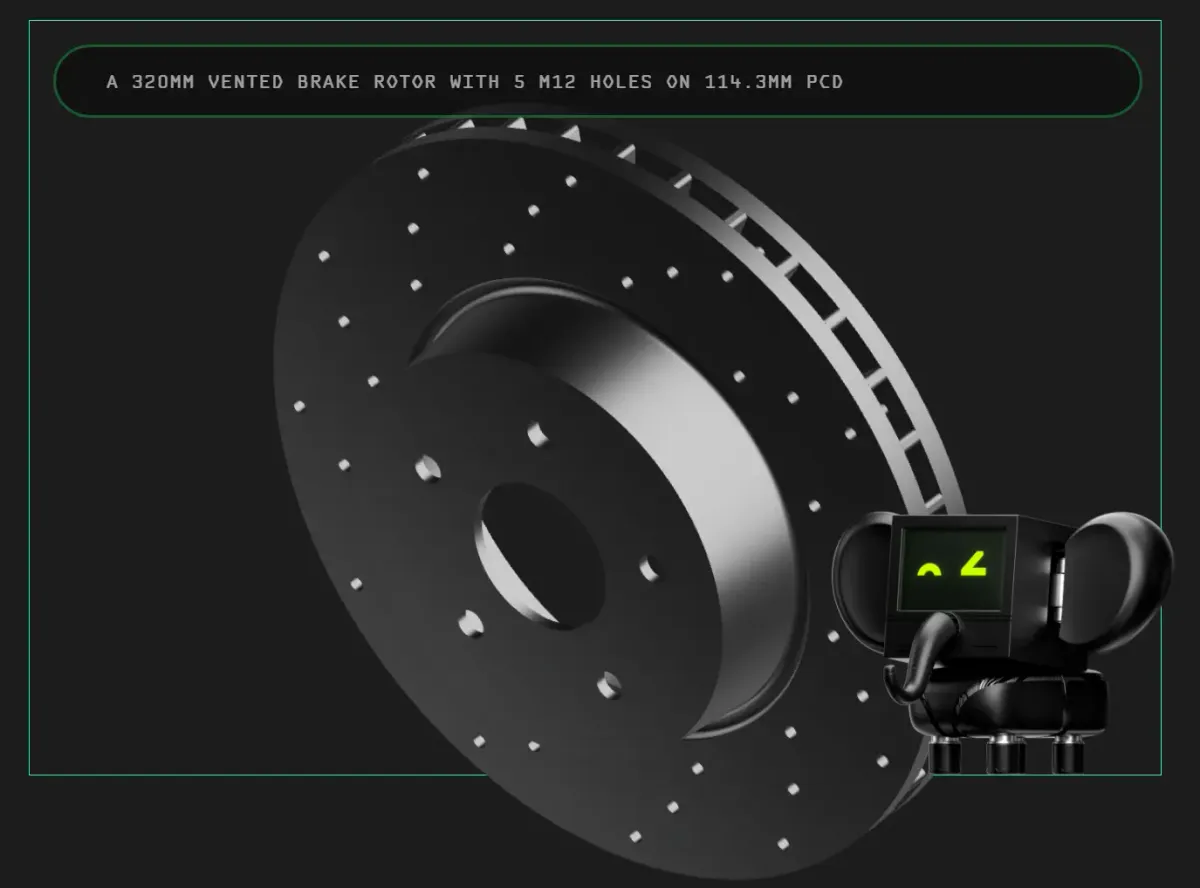

The workflow begins with Generative Topology Optimization. Instead of manual geometry creation, the human provides high-level constraints and performance targets via natural language.

- The Prompt: “Optimize a drone frame for maximum payload-to-weight ratio, ensuring sub-2kg total mass and mounting points for a camera.”

- The Action: The AI agent iterates through thousands of design permutations, performing real-time FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) simulations to select the most efficient structures.

Related:

- Text-to-CAD startups: Zoo (https://zoo.dev/text-to-cad), CADAM by Adam (CADAM is the open source text-to-CAD web application), CADScribe (https://cadscribelabs.com/)

- Vibe CADing tools as reviewed by Xometry on 2025-08-26 /Xometry/

- GenCAD-Self-Repairing: Feasibility Enhancement for 3D CAD Generation /arXiv/

2. Autonomous Procurement & Agentic Commerce

Once the design is viable, the system transitions from geometry to supply chain.

- The Action: The agent parses the Bill of Materials (BOM) and utilizes the Agentic Commerce Protocol (ACP) to interface with supplier APIs.

- The Intelligence: The AI agent optimizes for Total Cost of Ownership (TCO), balancing shipping lead times against material costs (e.g., choosing 7075 aluminum vs. carbon fiber based on current spot prices and project deadlines).

Related:

- A new era of agentic commerce is here /Google/

- Agentic AI in Industrial Goods: Driving Transformational Change /BCG/

- The agentic commerce opportunity: How AI agents are ushering in a new era for consumers and merchants /McKinsey/

3. Software-Defined Manufacturing Planning

The bridge between CAD and the factory floor is fully automated through Generative Process Planning.

- The Action: The system analyzes the 3D model to determine the optimal “make vs. buy” strategy. It generates toolpaths for CNC machining, slicing files for additive manufacturing, and any Automated Work Instructions.

- The Output: These instructions are high-fidelity digital twins of the assembly process, formatted specifically for consumption by robotic vision systems and LLM-powered actuators.

Related:

- BuildOS generates work instructions for complex mechanical assemblies. Drafts that traditionally take weeks or months now take hours or minutes. /Dirac/

- How Newton AI Is Transforming Manufacturing /Archetype/

- DeepMS: A data-driven approach to machining process sequencing using transformers /Journal of Manufacturing Systems/

- AutoSplit: a two-stage AI architecture for enhanced classification of manufacturing processes with a focus on the identification of additive manufacturing components /The International Journal of Advanced Manufacturing Technology/

4. Robotic Orchestration & Edge Execution

The final stage is the Physical Agency of the workflow, where the digital design becomes a finished good.

- The Action: A fleet of autonomous mobile robots (AMRs) or humanoid platforms receives the work instructions. Using foundation models for manipulation, the robots execute complex assembly tasks, such as fastener installation and wire harness routing, without the need for bespoke programming.

- The Result: A closed-loop feedback system where the robot identifies any manufacturing variances and feeds them back to the design agent for future iteration.

Related:

- “Robot, make me a chair” /MIT/